In recent years, stereolithography (SLA) has played a major role in the field of 3D printing, particularly within the medical and healthcare industries. With the use of this innovative technology, high-resolution and precise models can be created, which can be extremely useful for applications ranging from dental implants to surgical planning.

Let’s explore what makes stereolithography special, its applications in healthcare, and some interesting statistics.

What is Stereolithography?

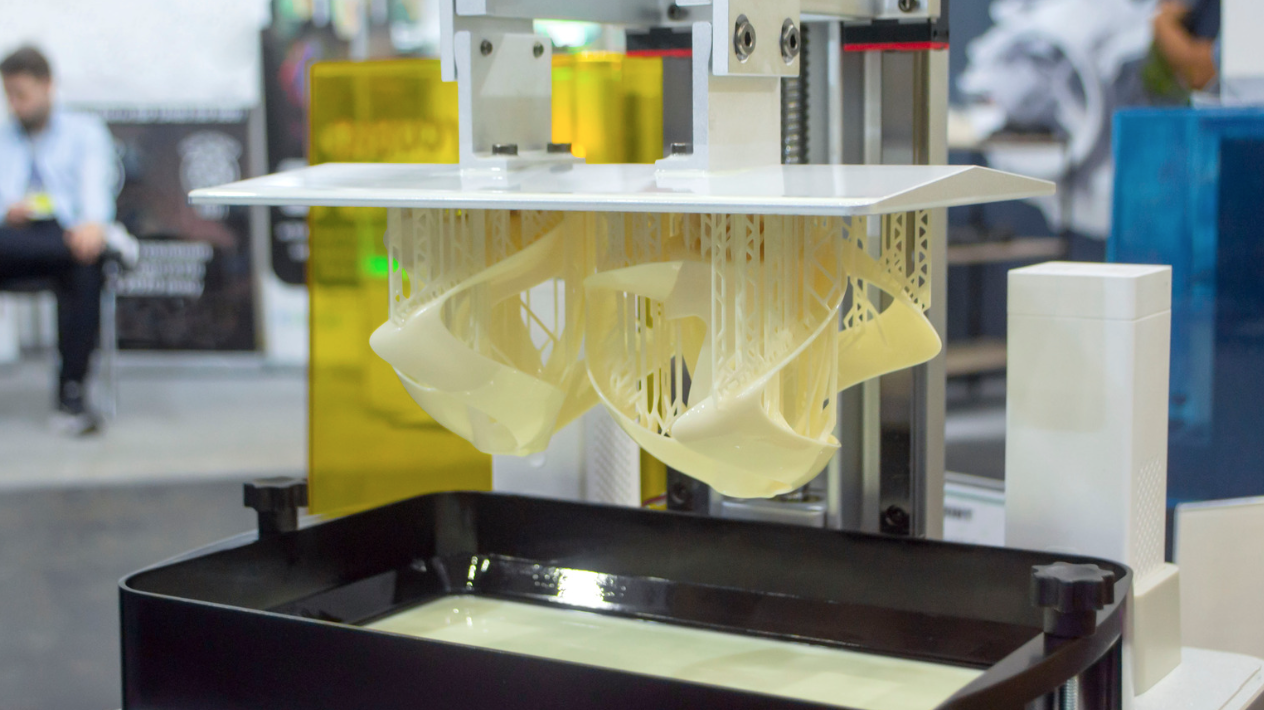

Stereolithography is additive manufacturing that involves using a laser to cure liquid resin into solid objects layer by layer. Charles W. Hull developed the technology in the early 1980s and has since become one of the most popular forms of 3D printing available on the market today.

This process includes the following steps:

➔ Layering Liquid Resin

During stereolithography 3D printing, a vat is filled with a specific liquid resin. When exposed to ultraviolet (UV) light, it becomes hardened. A UV laser then shines on the resin, curing it layer by layer. This method is dominant in making detailed shapes, which makes it perfect for intricate designs.

➔ Building Up Layers

As each layer of resin hardens, the build platform slowly lifts up. This gradual movement lets new layers stack on top of the ones that have already been set. The end result is a 3D object created layer by layer, which can achieve intricate shapes and details that traditional methods often find tough to pull off.

➔ Post-Processing

After the printing is done, the model usually needs a bit more work to make it stronger and look better. This means cleaning off any leftover resin and giving it some extra time under UV light to cure. These extra steps help with the durability and make sure the final product is up to standard for whatever it’s being used for.

Applications of Stereolithography in Healthcare

The healthcare industry has incorporated SLA technology in a variety of sectors.

Dental industry:

Stereolithography (SLA) is extensively used in dentistry to make precise and accurate dental models, crowns, and bridges. By ensuring the high level of accuracy of the technology, prosthetics will fit better, minimizing the need for adjustments and enhancing patient satisfaction.

Surgical planning:

Using SLA, surgeons are able to create detailed 3D models based on patient imaging data. By doing so, they are able to visualize complex anatomy. The goal of this preoperative planning tool is to improve surgical precision and outcomes by enabling customized surgical approaches.

Prosthetics:

A custom prosthetic device produced through SLA is tailored to meet the individual’s anatomical requirements. By personalizing prosthetic devices, patients who require prosthetic interventions can enhance their comfort and functionality.

Exciting Statistics

In healthcare, stereolithography plays an important role, as shown by some impressive statistics:

Market growth:

In the healthcare industry, the market for 3D printing is projected to reach $6.5 billion by 2025, and due to the precision and versatility of SLA technology, it is expected to become one of the major contributors to the market.

Efficiency gains:

The hospitals that have integrated 3D printing into their workflows have reported that they have been able to reduce the time spent designing custom devices and models by up to 30%.

Cost reduction:

SLA technology can help medical facilities reduce the cost of traditional manufacturing methods and improve the quality of patient care by reducing the costs associated with them.

The Future of Stereolithography in Healthcare

As tech keeps getting better, the future for stereolithography in healthcare looks really promising. We are expecting interesting stuff like biocompatible materials that can be implanted directly and faster, more accurate printers. Plus, there are efforts to create resins from renewable resources to tackle the environmental issues tied to plastic waste.

All in all, 3D printing using stereolithography is transforming the healthcare scene by providing an efficient, accurate, and customizable solution for various uses. As we delve a little further into this cool technology, it is clear we are only scratching the surface of its potential. So, whether you are in the healthcare field or simply a tech enthusiast, paying attention to these developments is definitely worth it!