What is 3D Printing? How does a 3D Printer work? is 3d printing hard We explain in detail this amazing futuristic technology.

Want to mend that broken handle? Why not print it with a 3D printer? Items break every day, and we usually have to replace them with new ones due to the unavailability of the broken parts. In such a situation, we often wonder about something that could create things when needed. Well, 3D printing technology gives us the tools to bring our imagination to reality. Not limited to modeling broken parts only, the applications of 3D printing technology are limitless. 3D printers are reshaping the manufacturing process across numerous sectors, be it technology, medicine, or architecture.

So, want to learn more about 3D printing technology? Read through this post and discover in-depth everything about 3D printing technology.

What is 3D Printing? Is 3d printing hard

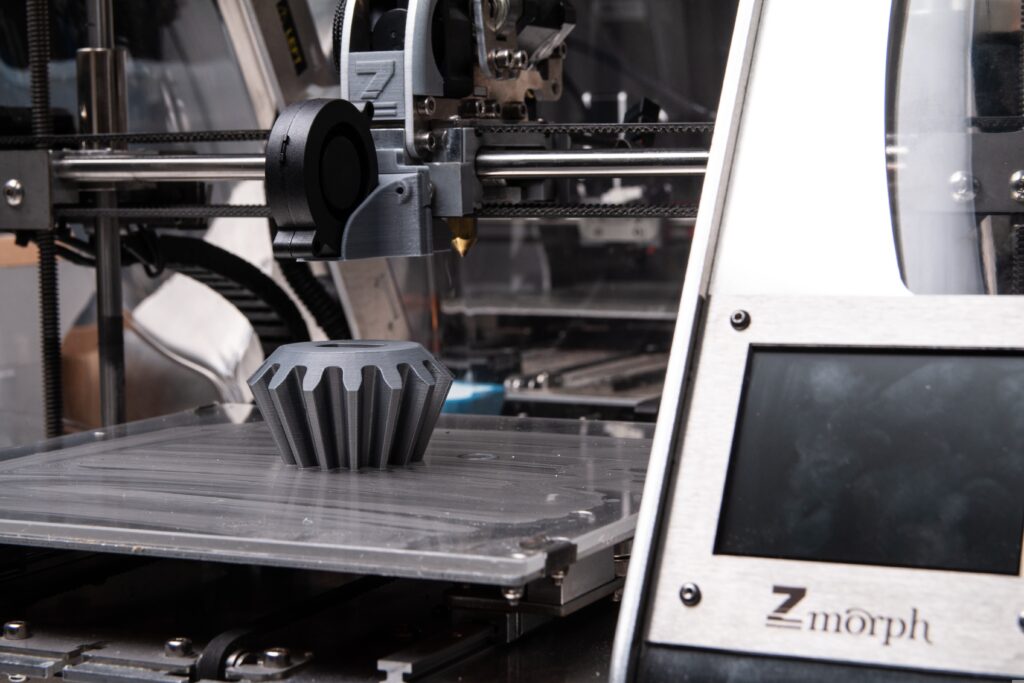

In simple terms, 3D printing involves a device or a machine generally referred to as a 3D printer to print a three-dimensional model of a digital image. How does it all work, you may ask? Well, a 3D printer deposits layer after layer of material according to a set pattern based on the 3D image of the object. The 3D printer keeps piling layers till the object takes its shapes exactly as the digital image. Since the object is modeled layer by layer, the procedure is also referred to as an additive process. It’s distinct from the subtractive process as the latter involves cutting or hollowing an object to give it the desired shape.

How 3D printing works

- Design: The process begins by creating a 3D digital model of the object using computer-aided design (CAD) software. The model is cut into thin horizontal sections, which serve as guides for the 3D printer.

- Print: The 3D printer reads these cross-sections and begins printing. Depending on the technology, printers can use a variety of materials, including plastics, metals, ceramics, or even organic compounds. Some popular 3D printing techniques include fused deposition modeling (FDM), stereolithography (SLA), and selective laser sintering (SLS). Layering: The 3D printer adds material layer by layer according to the instructions of the sliced digital model. This process is repeated until the entire object is created.

- Finishing: Once printing is complete, post-processing steps such as cleaning, painting, or assembly may be required to prepare the finished product.

Why 3D Printing?

3D printing technology is a paradigm-shifting approach to how we perceive and handle the manufacturing process. As such 3D printing holds tremendous potential to reshape the manufacturing process. Among its numerous benefits, the first is its extreme flexibility. A 3D printer can print a solid object using plastics or flexible objects using a combination of plastic and rubber powder. Moreover, it can also print industry-grade extremely strong objects using metallic powder and carbon fiber. Another advantage of 3D printing is its accuracy. Machine control process combined with computer-aided design produces a 3D model with extreme precision and accuracy, making it a promising tool to employ in prototyping, modeling healthcare machinery parts, and industrial manufacturing.

Accessibility will certainly grow as technology advances, making 3D printing more accessible and inexpensive for both consumers and small enterprises.

By generating goods on demand and lowering emissions caused by transportation, 3D printing has the potential to help reduce carbon footprints.

3D Printing: A Growing Industry

The adoption of 3D printing has seen a major spurt in recent years, mainly due to its huge application in almost every sector. While 3D printing was limited to specific prototyping in its early days, it is now rapidly replacing traditional manufacturing.

While the demand for 3D printing is still mainly from the industrial sector, it’s expanding rapidly to other sectors too. According to Acumen Research and Consulting, the numbers are promising, and by 2026, the global 3D market will grow to about $41 billion.

3D printing technology fulfills our dream of building things from our imagination. As it expands its reach, 3D printing technology will transform the way we make, design, and manufacture.

Conclusion

3D printing is a technology with limitless potential, redefining the way we produce, create, and innovate. Its impact spans many different sectors, bringing new possibilities and disrupting traditional manufacturing processes. As technology continues to advance, 3D printing promises to shape the future of design, manufacturing, and customization in ways we are just beginning to understand.